1 Introduction

2 Optimisation and generative Design (Restrict to 1000 phrases)

2.1 Objective searching for

Objective searching for is a operate embedded into CAD software program comparable to Stable Edge. The purpose searching for operate basically automates engineering calculations with out the necessity to rearrange equations and even might take away the necessity to develop equations (insert Quotation). The purpose searching for operate assumes the half the person has uploaded on CAD has an outlined geometry, space and quantity, then the person merely dimension’s the half and the purpose searching for operate finds the unknown parameter. Methods comparable to Hill climbing is used within the purpose searching for course of for sure CAD software program. Hill climbing works by initially sampling a degree at random, then taking a couple of different samples across the preliminary pattern. The algorithm then works out the most important worth and strikes to that time, then the method is repeated until the very best sampling level is discovered, which theoretically is the utmost worth (prime of the hill). The algorithm operates on the assorted engineering method and dimensions, as soon as the algorithm finds the utmost worth it can replace the person with sure half info comparable to variables and bodily properties.

2.1.1 Objective searching for instance:

2.1.1 Objective searching for instance:

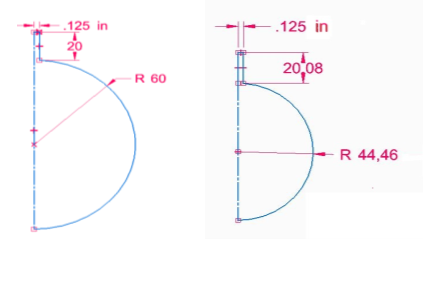

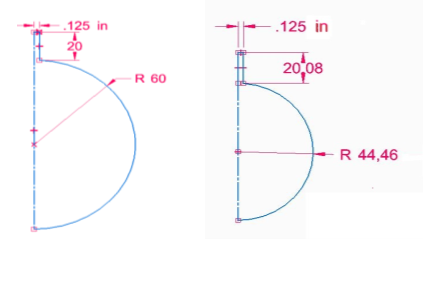

The instance above exhibits the purpose searching for operate in use. The 2, 2-D sketches characterize a Three-D half which is a dummy mass made out of aluminium. The target was to verify the half on the lefts mass, is 800g. Thus, after the purpose searching for operate was used, the half on the precise was created with the unknown parameters of radius proven to cut back to 44.46mm.

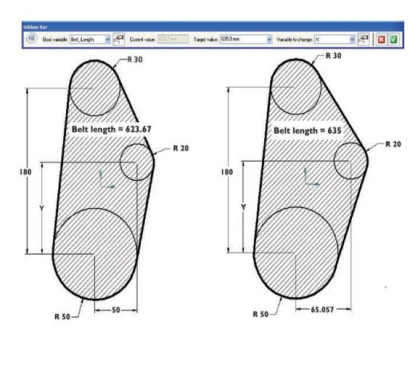

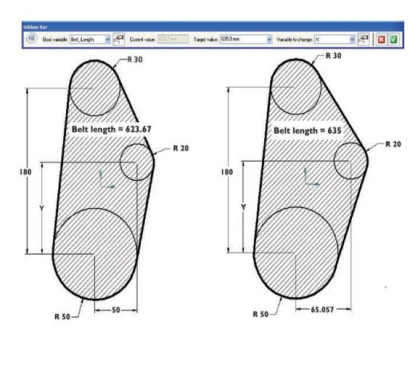

Determine 2 is a purpose searching for instance proven in a paper written by Siemens (insert quotation). The target was to extend a pulleys belt size from 623.67mm to 635mm, the particular worth that was discovered when the belt size elevated, was the underside wheel. Its dimension elevated from 50mm to 65.057mm with the remainder of the pulley’s components holding the identical dimensions.

2.2 Fundamental Optimisation Technique

2.2.1 What is supposed by optimisation and overview of space?

Optimisation within the laptop aided design context refers to, utilizing outlined search algorithms so as search the design house of an element or an meeting on CAD. As soon as the algorithms have completed looking out the house, sure design variables are altered by the algorithms so as to get hold of the optimum outcomes (insert quotation).

2.2.2 What’s unconstrained/constrained optimisation?

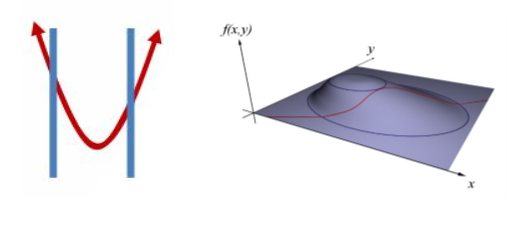

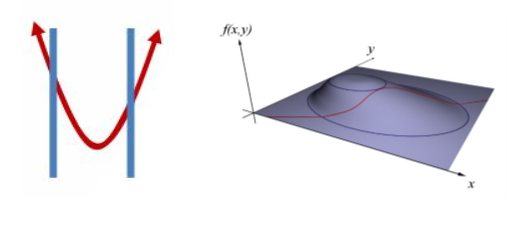

The constrained optimization downside is one the place you may need to maximise a sure analysis/goal operate which is perhaps some type of multi-variable operate i.e.

which should fulfill a number of equations as proven in equation 1. Which then you’re subjected to a sure constrains proven in equations 2 and three (insert Quotation). These constraints are a tough restrict that’s positioned on the worth of a variable that stops us from entering into sure instructions. Determine 2, clearly exhibits a visible illustration of a 2-D operate (on the left) and a Three-D operate (on the precise) that has been subjected by constrains.

An instance mathematical description of a constrained downside is proven under:

Maximise:

Topic to constraints:

The assorted sorts of constrained algorithms which can be helpful are as follows: Exhaustive search, Hill climbing, Gradient approaches, simulated annealing, Genetic algorithms and lots of different algorithms. Nonetheless, simulated annealing and genetic algorithms have been first constructed for unconstrained optimization which was then tailored for constrained optimization.

Unconstrained optimisation means, discover x and y such that

is a most, there is no such thing as a restriction on the vary of the operate. In some issues unconstrained optimisation issues seem instantly, nonetheless in some instances unconstrained optimisation come up on account of the reformation of constrained optimisation (insert Quotation).

2.Three Examples of optimisation

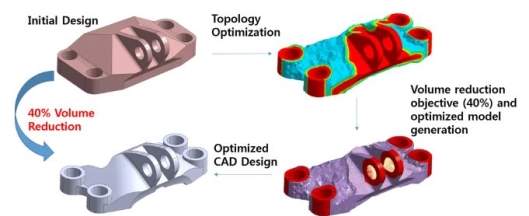

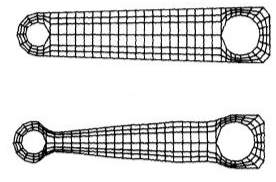

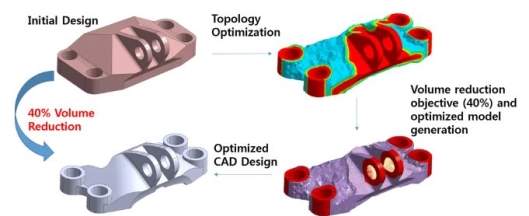

Determine () exhibits the optimization course of happening with an preliminary design that has gone by way of topological optimisation. A linear static evaluation is carried out on the preliminary design in-order to search out the assorted stresses and displacements. The software program then finds the areas the place the hundreds are the very best, which is then means extra materials is required and the areas the place the load are low, much less materials will probably be used. After the optimization course of it may be clearly seen that 40% of the amount is diminished as proven on determine (), producing a lighter, stronger and extra aesthetically pleasing design.

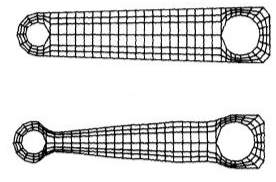

The image on Determine () exhibits optimization course of happening with an preliminary design of a torque arm that has been optimized by the finite-element based mostly optimization course of. On this case boundary situations have been utilized on the holes of the torque arm and a torsional drive as effectively. The pc then makes use of an built-in optimiser with the unconstrained algorithms so as to discover the optimized half.

2.Three Generative Design

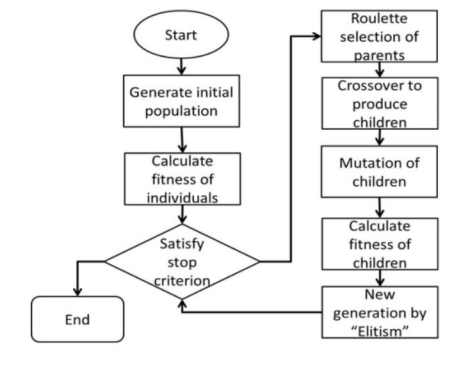

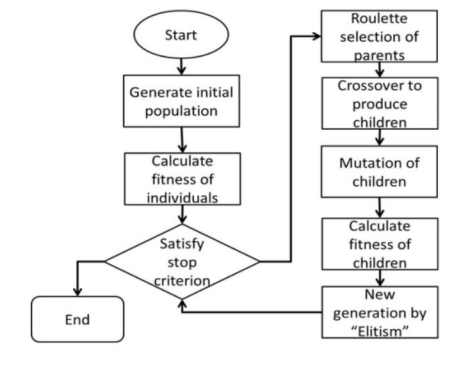

Generative design makes use of Darwinian Idea of pure choice, breeding and mutation so as to optimize a design and produce variants of a design. A designer or an engineer must specify sure enter design parameters i.e. weight, stiffness, price constrains and so forth. Into the CAD software program, then the software program explores all of the potential permutations through the use of cloud computing. When the software program is on the cloud it appears by way of all of the potential choices by testing configuration and studying from every iteration, so as to discover out what works and what doesn’t (insert Quotation). The testing and studying course of the software program conducts is feasible by means of a search algorithm known as the genetic algorithm. The genetic algorithm makes use of the precept of Darwinian Idea so as to discover the fittest people. Determine () proven under exhibits the essential mannequin used for a Genetic Algorithm.

The algorithm begins by producing an preliminary inhabitants which is a set of designs, totally different approaches are used so as to generate the set of designs. One instance is randomly deciding on designs from the design house. Then the algorithm begins to rank these preliminary designs, it makes certain that one of the best designs are chosen after which a mating pool is created which encloses one of the best designs. Then the algorithm recombines these designs so as to create new offspring from the randomly chosen mother and father that have been chosen from the mating pool. The kid produced is joined to the following technology. Lastly, the mutation takes place the place lacking info which the kid may not have acquired will probably be added into the gene pool. With the mutation happening the algorithm can lastly converge in direction of an accurate resolution, the place one of the best of finest in every technology and design is ranked and scored which exhibits that with every technology the design is improved. Then a set of one of the best designs will probably be proven to the person on the finish of generative design course of.

The limitation of Generative Design (What it could and may’t do)

Generative design improves an engineer’s design through the use of cloud computing and machine studying so as to discover a big set of options. Its objective is to not get rid of the engineer, however extra to broaden the identified set of options that the engineer has discovered with out utilizing the software program. Nonetheless, there are some limitation to generative design particularly in business

Three Reverse Engineering and Three-D Scanning (1000 phrases)

Understanding of various 3D file codecs?

intro and a few examples of file sorts (voxels, triangles, surfaces)

Three.1 Three-D file codecs (2 marks)

On this planet of Three-D scanning, knowledge is generally represented as a degree cloud with tens of millions of factors organized in an un-orderly trend which is saved in a file. It’s virtually not possible to create an ideal Three-D mesh of a mannequin because of issues comparable to muddle, reflectivity and areas missed, which makes it troublesome to acquire an entire spherical map of an object (insert quotation). So as to patch the areas of the mannequin which can be incomplete or exists as downside areas, it might be essential to sew a number of floor areas to type a Three-D triangle mesh mannequin.

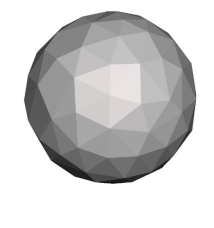

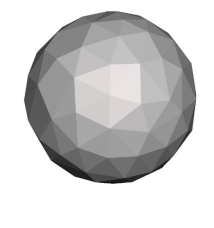

One of the widespread codecs used to retailer Three-D knowledge, is the STL file format. It has been established for nearly 20 years, because the business commonplace for supplying knowledge amongst design applications and different particular design software program comparable to Three-D printing or additive manufacture software program (insert quotation). The STL file encloses solely knowledge a couple of floor mesh however doesn’t include details about texture, color, materials and different vital properties. The floor mesh is made out of an unordered record of triangles, for each triangle 12 floating level numbers that represents it. For a 3D floor regular there are three coordinates that’s used to characterize the triangle. Because of this every vertex that’s adjoining with the opposite triangles needs to be repeated a number of occasions which results in inconsistencies, leaks and small rounding errors with the vertices that don’t precisely line-up.

Determine () proven on the left clearly exhibits a mesh of a ball that has been saved in a an STL file. The triangles representing every floor regular is proven to cowl the entire ball, as rounding errors of the vertices clearly dominant.

Three. 2 Benefits and Disadvantages of Mesh fashions (2 marks)

???

Three.Three Boundary Illustration (B-Rep) (1 mark)

Boundary illustration is a elementary knowledge construction that’s extensively used on this planet of geometric modelling. The underlying idea for the boundary illustration was developed independently by Ian braid and Bruce Vanguard at laptop Imaginative and prescient (insert quotation).

Boundary illustration is a elementary knowledge construction that’s extensively used on this planet of geometric modelling. The underlying idea for the boundary illustration was developed independently by Ian braid and Bruce Vanguard at laptop Imaginative and prescient (insert quotation).

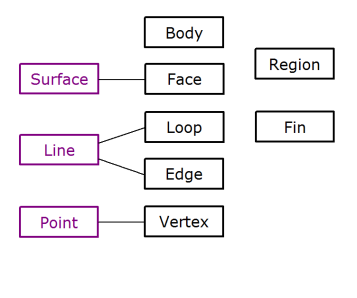

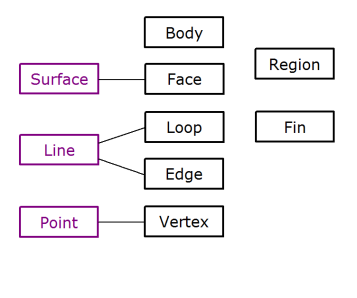

The fundamental instinct of B-Rep is proven within the determine (), which outlines the circulation of how the B-Rep works. A stable object has surfaces or faces that varieties its outer boundary. Every face has a set of boundary curves known as edges which outline its materials area. An edge has finish factors and vertices that outline its outer limits. This permits the B-Rep to deal with a set of surfaces as a single object.

B-rep has many benefits comparable to its ease when changing a B-Rep mannequin right into a wireframe mannequin, as a result of boundary’s definition being virtually equivalent to the wireframes. Nonetheless, the primary benefit is being able to assemble stable fashions from uncommon shapes, these shapes pose a serious downside when utilizing primitives to construct them (insert ct).

Three.four Options (2 marks)

??

Three.5 Three-D Scanning Course of (2 marks)

Three-D scanning is a extensively used methodology in design and engineering so as to analyse a bodily object, with the tip purpose being gathering knowledge of the form of the article. After the collation of information, Three-D fashions could also be constructed. Its functions in manufacturing is sort of dominant with areas comparable to reverse engineering, High quality assurance, Design Course of, Medical tools and As-built/as-is- modelling.

If we take the case of medical tools, it may be seen within the determine on the left Three-D scan is being product of an individual’s leg. The three-D scan permits for custom-fit components to the client, thus the affected person will obtain a prosthetic that’s custom match, with out the necessity of shopping for a basic prosthetic leg and adjusting it to suit the individual’s leg.

If we take the case of medical tools, it may be seen within the determine on the left Three-D scan is being product of an individual’s leg. The three-D scan permits for custom-fit components to the client, thus the affected person will obtain a prosthetic that’s custom match, with out the necessity of shopping for a basic prosthetic leg and adjusting it to suit the individual’s leg.

There are two predominant sorts of Three-D scanning applied sciences: Contact and non-contact. Contact applied sciences comparable to CMM (coordinate measuring machines) are very exact and correct scanning applied sciences, it’s because the scanning gadget is in direct contact with the half .100’000’s of information factors are being generated with the accuracy being all the way down to the micron stage, nonetheless this methodology possibly very correct however the whole course of is extraordinarily sluggish. Non–contact applied sciences comparable to construction mild, time of flight and triangulation is used to scan components and assemblies. If we take the instance of structured mild, it tasks a stripped sample on the article in both the visible vary of the infrared. The 2 digicam’s take a look at the stripped sample, which basically permits the digicam’s to select up advanced photos, comparable to options and edges through the use of advanced algorithms. Because the varied options might be recognised within the two digicam’s the depth of the article might be inferred. The issues with non-contact strategies is a few options could also be not recognised …. (Assignment help – Discuss reflectivity, muddle and a few areas’ which can be missed)

Three.6 Comparability to different strategies (2 marks)

Three.6 Comparability to different strategies (2 marks)

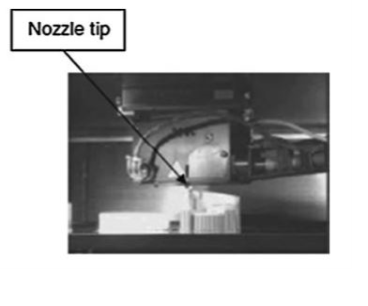

Strategies of measuring geometry, comparable to utilizing calipers and coordinate measurement will probably be in contrast on this part with respect to Non-contact Three-D scanners. Calipers are fairly liable to errors, a reference line of a specific measuring system introduces errors, when it doesn’t lie alongside the identical line because the dimension that’s being measured. Many occasions, the scales on the caliper are usually not in step with both the measuring faces or contacts. This implies the caliper will probably be liable to transferring round i.e. shifting and wiggling, which will increase error within the measurements. Three-D scanning eliminates the issues or place and stability as robotic arm scanners as proven within the picture on the precise successfully offers stability because the arm will probably be bolted to a secure floor won’t be vulnerable to vibrations (insert Quotation).

The areas the place Non- contact Scanning processes beat coordinate measuring instruments are pace, automation and value. Laser scanners can detect virtually hundred of thousand of factors and even tens of millions of factors per second, nonetheless the true query is the time that’s wanted to measure the standard of the half not a lot the pace.

Three.7 Complexity v accuracy (2 marks)

Commerce off between strategies

Three.eight Context of Reverse engineering (2 marks)

Reverse engineering within the context of design, is knowing the form of a bodily object by deconstructing it for the aim of understanding its design, manufacture or operate. On this planet of design an object would sometimes be reverse engineered so as to be exploited in CAD (IC). The primary makes use of of reverse engineering within the design and engineering world is as follows:

-

Understanding how a product works

-

Enhance an element or an meeting

-

Change an out-of-date half

-

Duplicate or copy a competitor

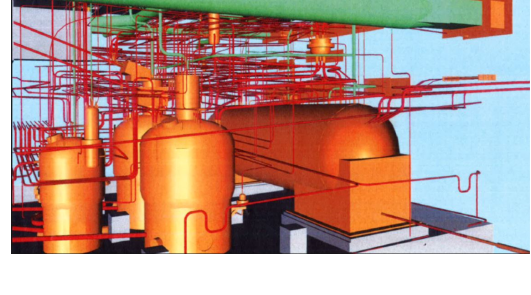

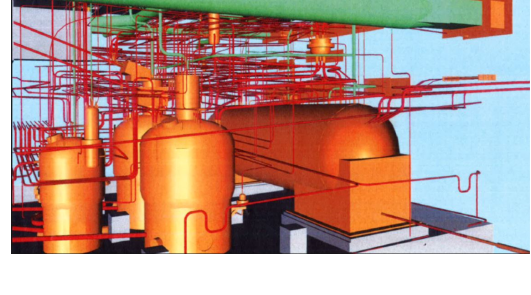

If an element is damaged or broken and may’t be traced again, reverse engineering may also help discover the half or get hold of the design of the half. Augmented actuality is a reverse engineering device that has been opted within the oil and fuel and nuclear industries. Within the nuclear business firms will put their staff by way of augmented actuality so as to practice them to decommission one thing earlier than the try to the true factor, which reduces disposal price. The picture under exhibits a scan of a web site at Sellafield the place the corporate has scanned the location after which made their staff use augmented actuality so as to have a way of the world and ensure the process is true for a submit operational clear out.

If an element is damaged or broken and may’t be traced again, reverse engineering may also help discover the half or get hold of the design of the half. Augmented actuality is a reverse engineering device that has been opted within the oil and fuel and nuclear industries. Within the nuclear business firms will put their staff by way of augmented actuality so as to practice them to decommission one thing earlier than the try to the true factor, which reduces disposal price. The picture under exhibits a scan of a web site at Sellafield the place the corporate has scanned the location after which made their staff use augmented actuality so as to have a way of the world and ensure the process is true for a submit operational clear out.

Within the oil and fuel business firms will use augmented actuality in order that they’ll practice their staff earlier than they go on sight and sort things, which reduces service prices.

(Assignment help – Discuss file retrieval, new fashions) and authorized elements

four.zero Additive Manufacturing (AM) (1000 phrases)

four.1 Introduction to Additive Manufacturing (1mark)

Additive manufacturing or Three-D printing has been described as revolutionizing product growth and manufacturing, with some folks going so far as saying “we’re experiencing a technological revolution” – David Rosen. AM refers to a course of of making components by including materials in layers. Each particular person layer is a skinny cross-section of a specific half that has been obtained from the CAD knowledge, which has been equipped to the Three-D printer. Since every layer is printed with a selected thickness, the ensuing half will probably be an approximation of the unique half. Thus, the thinner the layers are, the nearer the printed half will probably be to the unique (Insert Quotation). The supplies utilized in AM are primarily thermoplastics comparable to PLA, ABS, Nylon, TPU and PVA, these supplies have varied mechanical properties and differ in prices. The kind of materials used will rely upon the kind of utility and cost-constraints.

four.2 When to make use of additive manufacture (Advantages and Drawbacks) (2 marks)

The begin to finish technique of designing and manufacturing components have most undoubtedly been benefitted by AM. Components comparable to price, design, pace and high quality are the primary areas the place AM have a bonus vs conventional manufacturing. Many phases of producing have been eradicated, as conventional manufacturing processes wanted a number of and iterative phases in-order to create an element. Additionally, because the variety of options will increase the complexity of the half does as effectively. Which AM has no downside with coping with, whatever the complexity of the half, the manufacturing course of might be carried out in a single step (IC). This single step manufacturing technique of AM in comparison with different conventional strategies is far quicker as lesser time is taken as a result of compressed design cycles in AM.

(Assignment help – Discuss lighter and smaller quantity of waste)

The current advances in additive manufacturing expertise has allowed for the manufacturing of advanced components within the small, medium and huge scales. Regardless of additive manufacturing having the ability to produce medium and huge components many industries comparable to aerospace, automotive, oil and fuel and so forth. use additive manufacturing to supply smaller, core elements. This is because of AM processes having the ability to produce excessive stage of precision and adaptability when manufacturing small elements. One other think about why firms produce smaller components relatively than medium or massive is because of Excessive prices per half at scale, thus producing smaller elements is less expensive as bigger components deplete extra materials and vitality which will increase prices.

four.Three Additive Manufacture Course of (2 marks)

This part offers a deeper understanding of 5 out of the seven AM processes and discusses the advantages of every course of. The 5 additive course of that will probably be mentioned are as follows:

-

Vat photopolymerization

-

Powder Mattress Fusion

-

Materials Extrusion

-

Materials Jetting

-

Binder Jetting

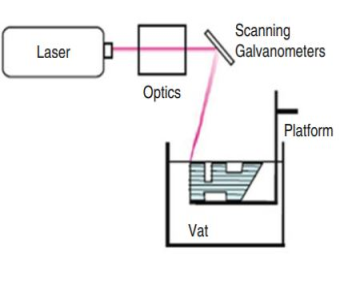

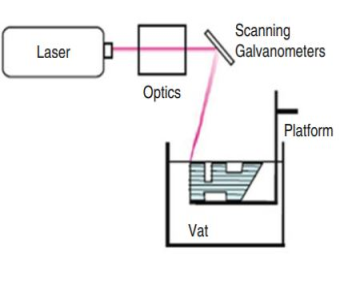

The Vat photopolymerization course of makes use of supplies comparable to radiation-curable resins or photopolymers. Ultraviolet radiation coupled with seen mild is used so as to remedy the supplies. The response that happens is known as photopolymerization whereby the supplies bear a chemical response, in consequence the fabric turns into stable.

The determine above exhibits schematic illustration of a Laser scan Vat Polymerization, it may be seen that the scan produces stable components by solidifying the liquid photopolymer resin utilizing an UV laser. The bodily half is made by staking slices on prime of one another. When every slice is accomplished, the platform will probably be lowered, then the floor of the slice will probably be coated right into a vat of resin. This course of will probably be repeated until the half is accomplished. The benefits of this course of are that it produces very correct and clean components at a comparatively excessive pace, nonetheless the components are fairly brittle and thus are usually not utilized in functions that require robust structural properties.

Energy Mattress fusion processes works through the use of a thermal supply, on this case a laser is used in-order to advertise fusion between the particles of powder. The ability is generally unfold throughout the entire construct platform after which the laser heats sure areas of the powder which solidifies the powder. Lots of the powder within the course of stays used and might be recycled for the following fusion course of.

Materials Extrusion

four.four Examples of AM in engineering (2 marks)

four.5 Fused deposition modelling (FDM) 3D printing intimately (2 marks)

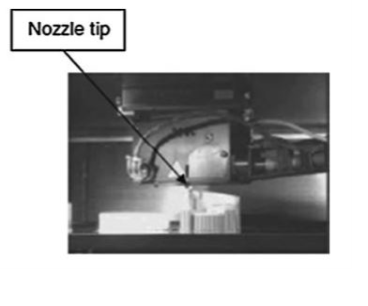

Fused deposition modelling is the commonest extrusion-based AM expertise available in the market. The way in which FDM works is, it makes use of a heating chamber which liquefies the polymer, this polymer would have been fed into the FDM system as a filament. An extrusion strain is generated within the chamber when the filament is being pushed out to supply a layer on a construct plate, a tractor wheel association permits for this to occur. After ever layer is produced, the construct plate lowers and the following layer is constructed up until the complete half if manufactured. This course of is proven within the determine under.

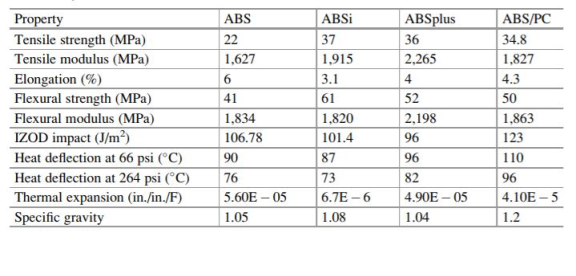

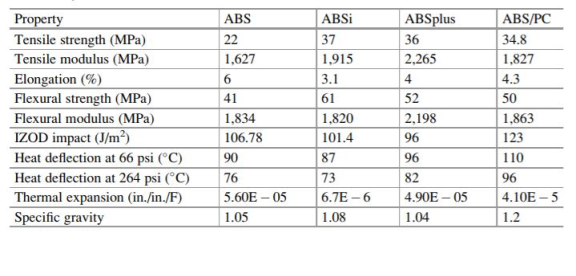

Probably the most generally used materials in FDM is the ABS materials, there are different variation of ABS supplies comparable to ABSi, ABSplus and ABS/PC that are extensively out there. The tensile properties of those materials range, because the person can select which type of materials, they want relying of the structural hundreds the half will probably be experiencing. ABSi nonetheless offers a translucent impact which may add to the aesthetic of manufactured half. ABSi and ABSplus each have excessive tensile strengths of between 36Mpa to 37Mpa and now have larger tensile modulus and thus can be utilized for components which can be expertise heavy hundreds. ABS by itself has the very best elongation % which is appropriate for utility which may expertise hundreds over its Final tensile power.

Probably the most generally used materials in FDM is the ABS materials, there are different variation of ABS supplies comparable to ABSi, ABSplus and ABS/PC that are extensively out there. The tensile properties of those materials range, because the person can select which type of materials, they want relying of the structural hundreds the half will probably be experiencing. ABSi nonetheless offers a translucent impact which may add to the aesthetic of manufactured half. ABSi and ABSplus each have excessive tensile strengths of between 36Mpa to 37Mpa and now have larger tensile modulus and thus can be utilized for components which can be expertise heavy hundreds. ABS by itself has the very best elongation % which is appropriate for utility which may expertise hundreds over its Final tensile power.

four.6 FDM design consideration (Three marks)

four.6 FDM design consideration (Three marks)

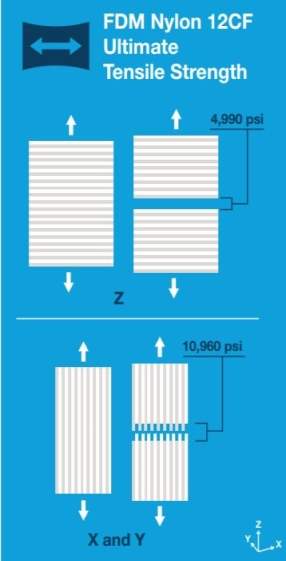

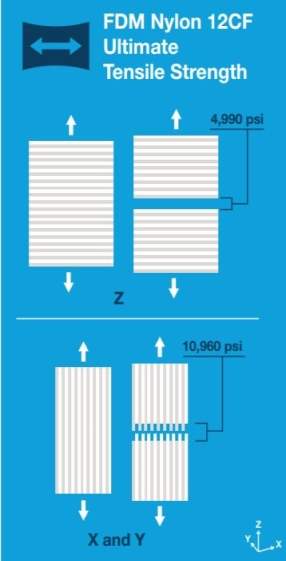

One of many predominant design concerns customers ought to take when manufacturing an element utilizing FDM is the anisotropic half power. Anisotropic half power happens in FDM as a result of layer-by-layer deposition of the system. This implies the tensile power of the fabric is stronger within the x-y course in comparison with the y-direction. To keep away from this problem, construct orientation, half geometry and pre-processing strategies can be utilized to mitigate these issues. AM software program offers the person with varied power worth for the totally different orientations.

That is illustration of stronger tensile power within the x-y course and weaker power on the y-direction is proven on the precise.

So as to mitigate utilized stress, compression, bending, shear and torsional loadings for FDM tooling, the shortest potential load half ought to be taken. The AM software program comprises instruments comparable to topology optimization which provides the person details about how the fabric will probably be distributed.

Components comparable to creep can have an effect on the manufacture of components in AM, thus one method to take care of this downside is by designing mounting and put on factors, by both utilizing ceramic or metallic inserts. These inserts will assist with the half from dynamic overload or from excessive static forces (IC).

Determine 13: Anisotropy exhibits the z airplane is the weakest airplane

2.1.1 Objective searching for instance:

2.1.1 Objective searching for instance:

Boundary illustration is a elementary knowledge construction that’s extensively used on this planet of geometric modelling. The underlying idea for the boundary illustration was developed independently by Ian braid and Bruce Vanguard at laptop Imaginative and prescient (insert quotation).

Boundary illustration is a elementary knowledge construction that’s extensively used on this planet of geometric modelling. The underlying idea for the boundary illustration was developed independently by Ian braid and Bruce Vanguard at laptop Imaginative and prescient (insert quotation).

If we take the case of medical tools, it may be seen within the determine on the left Three-D scan is being product of an individual’s leg. The three-D scan permits for custom-fit components to the client, thus the affected person will obtain a prosthetic that’s custom match, with out the necessity of shopping for a basic prosthetic leg and adjusting it to suit the individual’s leg.

If we take the case of medical tools, it may be seen within the determine on the left Three-D scan is being product of an individual’s leg. The three-D scan permits for custom-fit components to the client, thus the affected person will obtain a prosthetic that’s custom match, with out the necessity of shopping for a basic prosthetic leg and adjusting it to suit the individual’s leg.

Three.6 Comparability to different strategies (2 marks)

Three.6 Comparability to different strategies (2 marks)

If an element is damaged or broken and may’t be traced again, reverse engineering may also help discover the half or get hold of the design of the half. Augmented actuality is a reverse engineering device that has been opted within the oil and fuel and nuclear industries. Within the nuclear business firms will put their staff by way of augmented actuality so as to practice them to decommission one thing earlier than the try to the true factor, which reduces disposal price. The picture under exhibits a scan of a web site at Sellafield the place the corporate has scanned the location after which made their staff use augmented actuality so as to have a way of the world and ensure the process is true for a submit operational clear out.

If an element is damaged or broken and may’t be traced again, reverse engineering may also help discover the half or get hold of the design of the half. Augmented actuality is a reverse engineering device that has been opted within the oil and fuel and nuclear industries. Within the nuclear business firms will put their staff by way of augmented actuality so as to practice them to decommission one thing earlier than the try to the true factor, which reduces disposal price. The picture under exhibits a scan of a web site at Sellafield the place the corporate has scanned the location after which made their staff use augmented actuality so as to have a way of the world and ensure the process is true for a submit operational clear out.

Probably the most generally used materials in FDM is the ABS materials, there are different variation of ABS supplies comparable to ABSi, ABSplus and ABS/PC that are extensively out there. The tensile properties of those materials range, because the person can select which type of materials, they want relying of the structural hundreds the half will probably be experiencing. ABSi nonetheless offers a translucent impact which may add to the aesthetic of manufactured half. ABSi and ABSplus each have excessive tensile strengths of between 36Mpa to 37Mpa and now have larger tensile modulus and thus can be utilized for components which can be expertise heavy hundreds. ABS by itself has the very best elongation % which is appropriate for utility which may expertise hundreds over its Final tensile power.

Probably the most generally used materials in FDM is the ABS materials, there are different variation of ABS supplies comparable to ABSi, ABSplus and ABS/PC that are extensively out there. The tensile properties of those materials range, because the person can select which type of materials, they want relying of the structural hundreds the half will probably be experiencing. ABSi nonetheless offers a translucent impact which may add to the aesthetic of manufactured half. ABSi and ABSplus each have excessive tensile strengths of between 36Mpa to 37Mpa and now have larger tensile modulus and thus can be utilized for components which can be expertise heavy hundreds. ABS by itself has the very best elongation % which is appropriate for utility which may expertise hundreds over its Final tensile power.

four.6 FDM design consideration (Three marks)

four.6 FDM design consideration (Three marks)